The 3D Printer Filament Recycler’s Guide

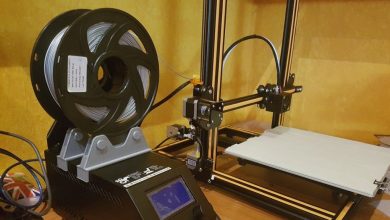

Turn your 3D printed waste into new spools using a 3D printer filament recycler. The typical recycler will smash failed prints into smaller pieces, melt them down, and force the liquid plastic through an opening. The hot plastic is then cooled down and coiled onto a reel.

Some tips when using a 3D printer filament recycler:

- Don’t mix different types of filaments. Doing so may lead to undesirable printing results.

- Ensure your filament or plastic is clean and separated. For example, it is highly likely that you will get better results when you use plastic that has the same chemical composition.

Not all machines are able to both shred and extrude. This means that, depending on your needs, you may have to buy two machines.

Shredding

You can make a DIY shredder or purchase a ready-made shredder like the SHR3D IT. The Filabot Reclaimer is another great option — compatible with HIPS, PLA, and ABS — even though it is currently out of stock.

It’s important to note that shredding plastic can be a bit tasky for the average DIYer. This is primarily because grinding plastic puts a strain on the ordinary motors found in commercial appliances. A simple solution is to get an industrial shredder with a powerful motor, but in this case, be ready to spend more.

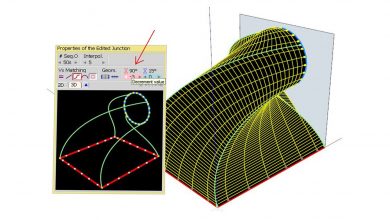

Extrusion

There are several extruders in the market, ranging from DIY extruders to plug-and-play machines.

Here are a few examples of extruders you can buy:

- Open source options include the Recyclebot or the Lyman/Mulier Filament Extruder.

- Filastruder Kit: The Filastruder Kit will extrude PLA without any trouble, but you have to ensure that the polymer is thoroughly dried before extruding. PLA requires extra cooling and a winder with a clear and clean space for it to coil. ABS will also work well in the Filastruder. Other polymers that can be successfully extruded by the Filastruder Kit include PVA, PC, PMMA, Acrylic, TPE, PEEK, and PCL, among others.

- Strooder: Strooder has a touchscreen interface and comes pre-loaded with extrusion settings for PLA and ABS. It will also work well with PP, Nylon, and PE.

- Filabot EX2 filament extruder: Works with a wide range of polymers, including PC, PS, PEEK, HIPS, PLA, ABS, and several others.

- FilaFab Extruders: The 100 series are ideal for producing PLA and ABS filament, but they have a low volume and are designed for short runs. On the other hand, the 350 series will work with more materials, including Nylon and HDPE. The Pro 350 and the Pro 350 EX are ideal for those makers who have a higher demand for filament.

- Noztek Pro: Noztek Pro works with a range of polymers, including HDPE, ABS, PET, PP, PLA, and many more.

1.1. Shred and Extrude: The ProtoCycler

The ProtoCycler is the quintessential 3D printer filament recycler because it can perform both shredding and extrusion. It represents a great way to reuse your scrap filament from failed prints or from small bits of filament that would typically go unused.

This 3D printer filament recycler is the work of former classmates David Joyce and Alex Kay, who were fed up with purchasing expensive filament. They joined forces and built a machine that could recycle their material for them.

The result was the ProtoCycle, which grinds plastic into digestible pieces, melts the plastic down, extrudes it, and coils it onto a spool. This device is computer-controlled to ensure consistency.

Using this type of machine at home is more demanding compared to using a regular 3D printer. Nevertheless, it’s accessible to any dedicated DIYer who cares about plastic waste.